Build Exam Readiness into Daily Shop Routines

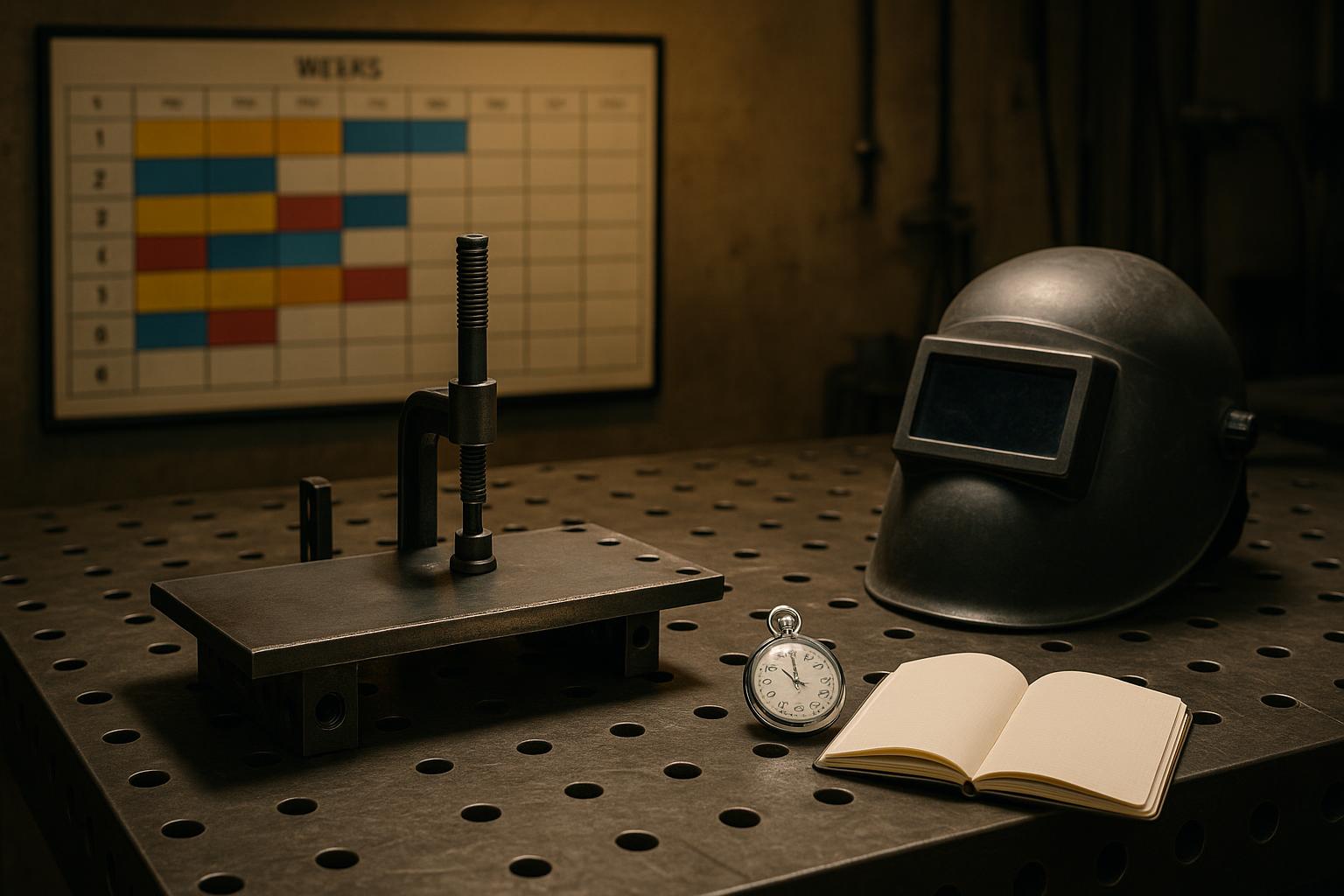

Running an eight-week sprint for certification prep helps busy welders weave practice into the daily workflow without derailing production. The plan emphasizes fixtures, mock exams, and mindful stress management to perform confidently during lab day.

Why an 8-week sprint works

Eight weeks gives you a cadence for fixture practice, mock exams, and stress management. It reduces last-minute rush and fatigue on lab day. You can adapt to your schedule by replacing longer blocks with shorter sessions during peak periods.

Frame a repeatable weekly plan

Outline a practical micro-schedule that builds skills day by day: steady fixture mastery, controlled bead sequences, and rapid inspections. Each week should have a clear objective, a minimum set of coupons to weld, and a quick reflection log to capture what went well and what needs adjustment.

To align your plan with proven strategies, check Mastering Certification Registry Prep for registry workflows and documentation. You can also reference the Certification Timeline Toolkit to set weekly milestones.

Practical fixtures and mock exam setup

In the early weeks, integrate dedicated fixture work into fabrication tasks: clamp in jigs, practice bead sequences, and run coupons that mimic lab joints. Run short, timed mock exams on the bench to simulate lab constraints. For practical tips, see Welding Certification Hacks: Prep Like a Pro.

Stress management and fatigue

Stress control is part of the plan; schedule 5-minute breaks, paced breathing, and hydration to sustain performance. For more on pressure handling in certification, refer to Certification Testing Under Pressure.

Putting it all together

By Week 8 you should feel ready for lab day with a bank of practice coupons, validated settings, and a simple reflection log. This structure helps you stay consistent and reduces anxiety as exam day approaches.