Expert Strategies for Multi-Process Sequences in Complex Structures

Thick-to-thin joints present a unique set of challenges. Proper sequencing and heat management are critical to avoid distortion on the thin leg while achieving full penetration on the thick portion. A practical approach combines GTAW for a tight root with GMAW for robust filler and finish.

For context on thick sections, see thick section mastery.

Joint preparation and beveling for thick-to-thin joints

Bevels should provide adequate root penetration without overburdening the thin plate. On typical carbon steels, a 30–45 degree bevel with a 0.8–1.2 mm root gap works well; adjust for aluminum and stainless per material data sheets. Scrupulous cleaning and fit-up prevent arc blow and porosity. Tactics like staggered tack welds help maintain alignment as heat is applied.

Heat input control and sequencing

Start with GTAW root to establish fusion with lower heat input. Move quickly into a filling pass with GMAW or FCAW, using a larger diameter electrode to deposit material efficiently. Maintain a steady travel speed and modest voltage to keep the thin portion from overheating. For more on strategic process choices in complex joints, see hybrid process strategies.

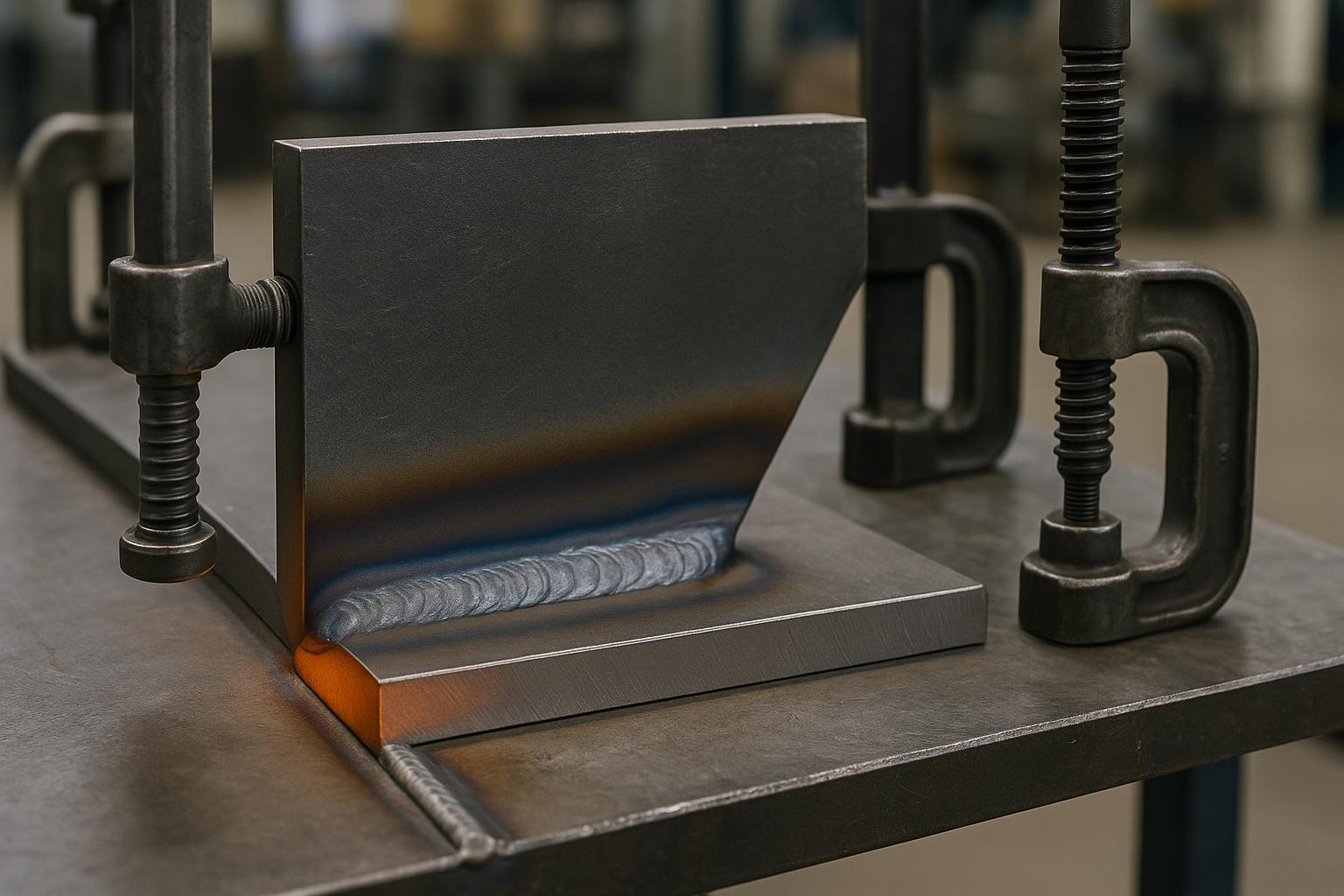

Practical example: a GTAW root, then GMAW fill on a thick-thin joint

In a test configuration, a 1-in-thick thick plate is joined to a 1/4-in thin plate. A GTAW root is welded with 1.6 mm tungsten, argon shielding, and a low heat input. The fill is then deposited with a short-circuit transfer GMAW using .045″ ER70S-6 wire. Preheat steel to 150–200°F as needed. The result is a clean root and stable cap with minimal distortion on the thin leg.

Tip: choose joint geometry that distributes heat, such as a double-V or step-bevel, and clamp the assembly to minimize distortion. If you want more on process planning, have a look at the advanced process playbook.

With careful sequencing and proper prep, thick-to-thin joints can be reliable with multi-process sequences. Practice in test plates and document heat input data to replicate success on real structures.