Using Sensor Data to Predict Weld Defects Before They Form

Real-time arc analytics leverage sensor data from the welding arc to detect deviations that precede porosity, lack of fusion, or crater cracks. By tracking current, voltage, arc length, travel speed, and heat input across passes, the system can spot drift before a defect shows up on the weld bead.

On the shop floor, AI-powered arc monitoring translates raw measurements into actionable guidance. When current or arc length drifts out of spec, the system can prompt an immediate adjustment to wire feed, travel speed, or shielding gas to keep heat input within target windows. This reduces rework and helps you stay within certification tolerances.

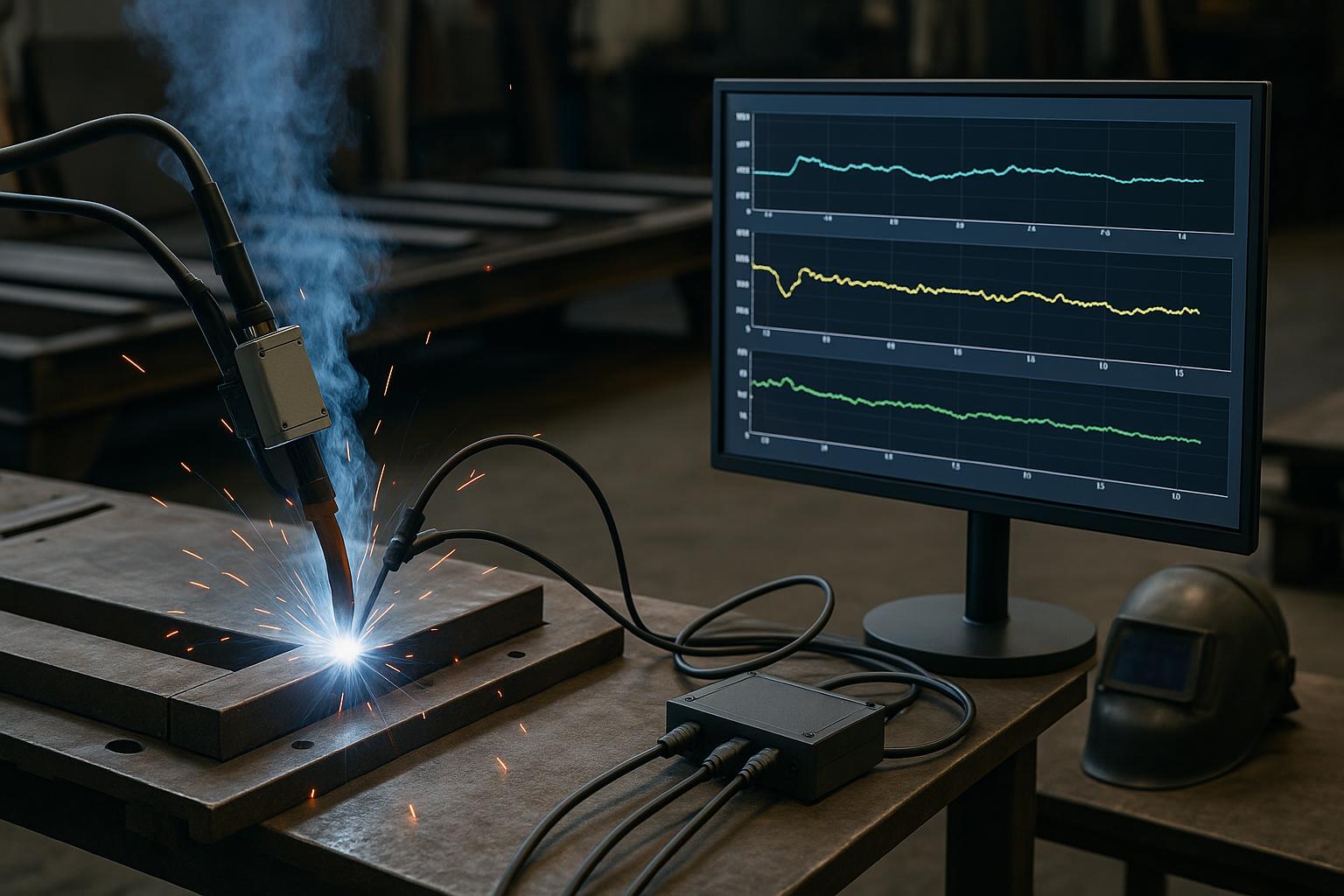

A practical workflow: connect sensors to a data hub, run models on a local controller, and display a live dashboard. When the model predicts a defect risk above a threshold, the operator is prompted to adjust parameters to stay within spec. This approach supports data-driven certification prep by giving welders repeatable, auditable responses during tests.

In a case study of arc-length monitoring during a thick-section weld, the system flagged a rising arc length and current drift; adjusting voltage and travel speed stabilized the bead and kept it within spec.

To start, pilot on a common weld, attach a compact sensor package, and validate the workflow on certification tasks. Real-time arc analytics let you tune heat input on the fly, reducing defects and rework over time.