Field-Proven Process Choices, Setup Tips, and Test Considerations for Mobile Shops

Onsite welding processes demand a practical playbook that balances weld quality with field realities. This guide outlines field-proven process choices, setup tips for mobile shops, and test considerations you’ll encounter when servicing customer sites. Use these guidelines to choose reliable welding methods, optimize your equipment, and plan inspections before you arrive on site.

Process choices for field work

Choosing the right onsite welding processes hinges on material type, joint design, access, and weather. When you need productivity without compromising quality, start with three core options and tailor from there.

Structural steel and thick plates

- GMAW (MIG) or FCAW (flux-cored) are workhorse choices for flat and fillet welds on structural steel in the field. Use FCAW-G (gas-shielded) or FCAW-S (gasless) depending on wind and gas availability.

- For root passes in thicker sections, consider a short-circuit GMAW root with FCAW fill and a final cap, balancing speed and penetration.

Pipe, girth welds, and joints with access limits

- FCAW-S or GTAW for root passes when wire handling is challenging in confined spaces.

- For larger-diameter pipe in outdoor settings, FCAW-G provides robust deposition with less shielding gas handling.

Thin materials and precision welds

- GMAW-Pulse or GTAW offers better control on thin sections and critical joints.

- Reserve TIG only when heat input must be minimized or where cosmetic quality is paramount.

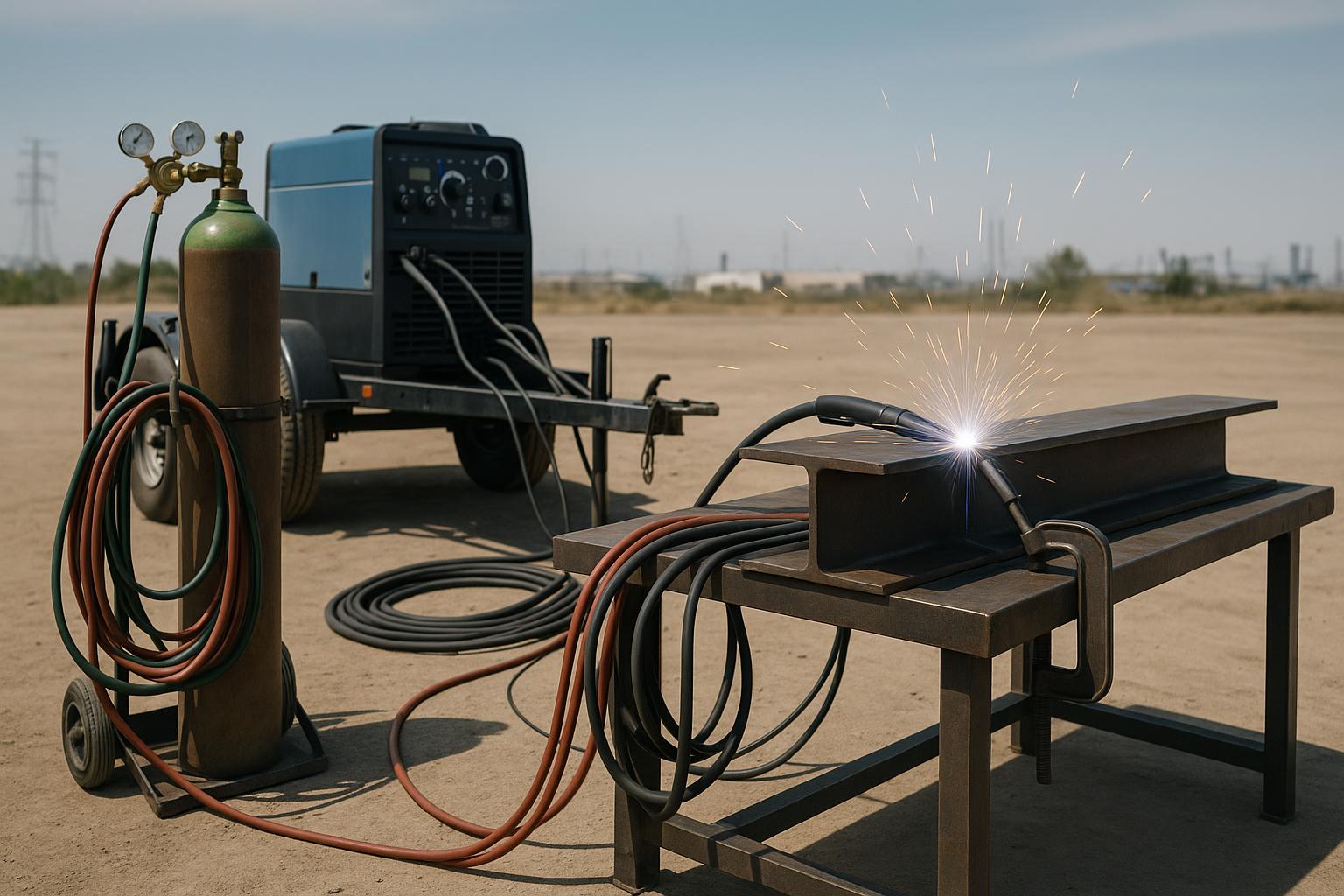

Equipment setup tips for mobile shops

Field setups should be organized for quick access, safe operation, and reliable power. Plan for power supply, gas or flux, and safe stowage of consumables.

Power, feeders, and cables

- Match the generator or site power to your process to avoid voltage dips that affect arc stability.

- Use properly rated wire feeders and push-pull setups for longer runs or when using flux-cored tubing.

Gas, flux, and shielding considerations

- Choose flux-cored wire for windy sites to minimize shielding gas requirements, or use regulated shielding gas for gas-shielded processes when conditions allow.

- Keep gas cylinders secure and hoses away from heat sources or sparks; inspect hoses for leaks before each shift.

Safety and workspace layout

- Secure the work area, mask exhaust vents, and use ground clamps properly to minimize shock risk.

- Arrange a compact, weather-protected area with a stable table, clamps, and spare parts within easy reach.

Test considerations and documentation

Plan testing early with the client and inspector. On-site tests focus on process verification and weld quality, plus record-keeping for compliance.

Pre-weld and post-weld testing basics

- Pre-weld: review WPS and PQR, verify material spec, and confirm joint geometry.

- Post-weld: perform visual inspection (VT) and, if required, non-destructive testing (NDT) such as magnetic particle (MT) or liquid penetrant (PT) depending on codes.

Documentation and deliverables

- Capture bead profiles, setup parameters, and any deviations from the WPS for client records.

- Prepare concise inspection reports and retain records for traceability and future audits.

Field-ready checklist

- Verify joint design, material spec, and WPS alignment.

- Confirm power and gas/flux supplies and inspect hoses and cables.

- Secure safety gear, fall-protection where required, and site-specific permits.

- Plan for weather and site conditions and have a contingency plan for power outages.

By keeping these elements in your field playbook, you can deliver consistent weld quality, minimize downtime, and speed up customer turnover on mobile projects.