When to Bring in TIG-Assisted MIG for Certification-Friendly Welds

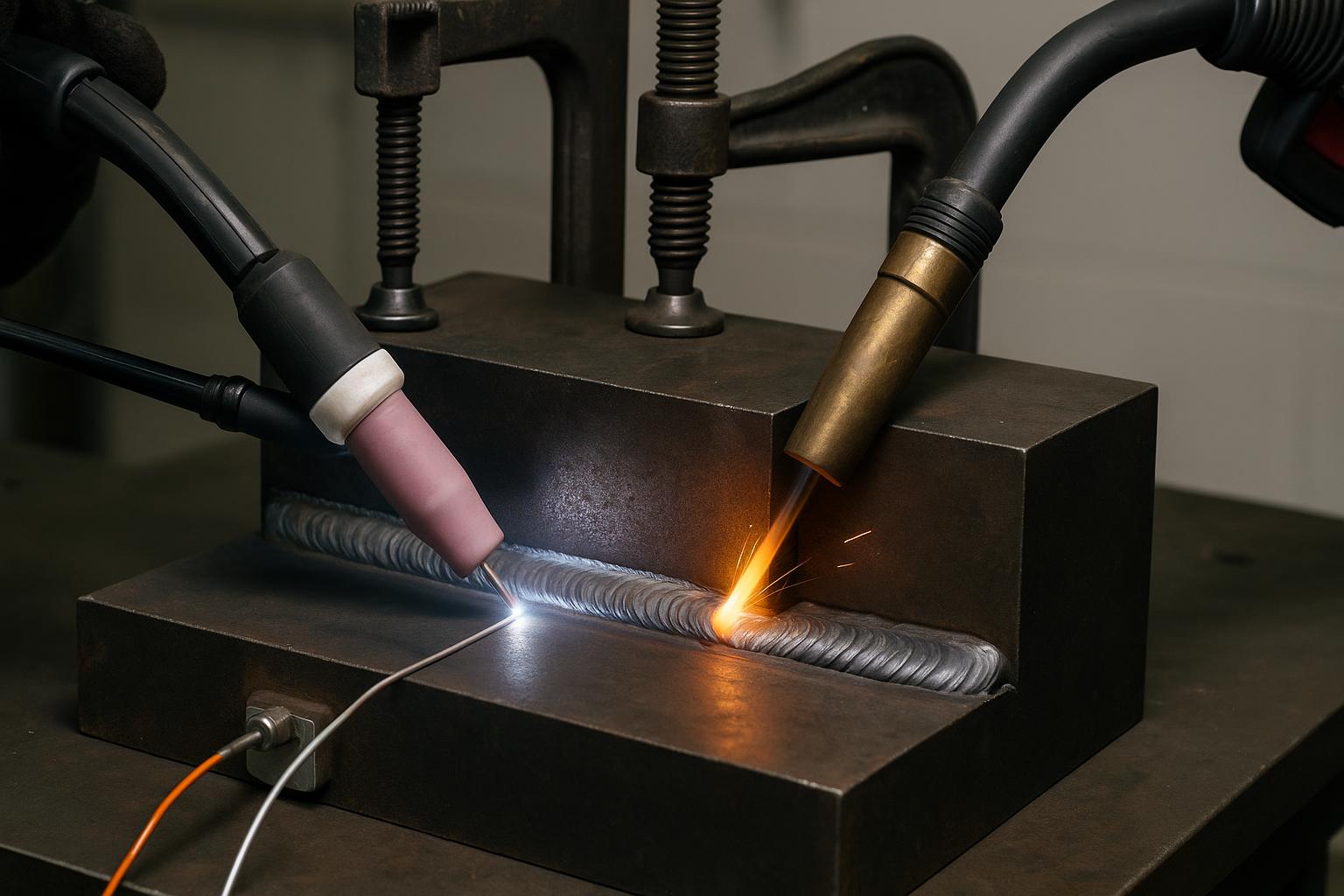

Multi-process welding can be the sweet spot for joints that push the limits of fit-up, heat control, and certification requirements. A TIG root pass paired with MIG filler can deliver clean weld roots with dependable deposition while keeping the process within typical lab documentation standards.

Use this approach when the joint geometry demands high root quality but the required surface finish and fill are cost-sensitive. In practice, you sequence the TIG root to establish the weld geometry, then switch to MIG for the bulk fill. This helps manage heat input by isolating the high-precision portion of the weld from the faster deposition portion.

Key decision factors for a certification-friendly joint

- Joint fit-up and root quality: A TIG root offers precise control over penetration and root fusion, which labs often require for qualifications. If fit-up is imperfect, plan MIG filler passes that do not mask root defects.

- Heat input management: TIG runs generate lower heat in the root but slower deposition; MIG fills add more heat. Analyze the total heat input to avoid distortion that could invalidate lab tests.

- Material, thickness, and position: For thick sections or tight positions, a TIG root can improve access and control; MIG filler can finish in position with consistent deposition.

- Lab requirements and documentation: Certification labs typically require traceable parameters and PQR/WPS alignment. Plan to document each process parameter for root and fill passes, and keep records organized.

- Scrap and rework risk: A robust plan minimizes rework by clearly separating the root and fill phases, reducing the chance of rework due to heat-related defects.

Practical sequencing and parameter tips

Start with a tight root pass in TIG, using a conservative heat input and back-step technique to control penetration. Then switch to MIG for the remainder of the joint, focusing on consistent bead height and breadth. If the lab requires a particular weld map, align your sequence to the lab’s documented WPS.

Plan your root pass and fill passes around the lab’s acceptance criteria. For example, a TIG root may require lower interpass temperatures to preserve fit-up, while MIG filling can be adjusted with wire feed speed to maintain deposition rate without overheating the joint. For guidance on selecting a plan, see the process-selection playbook and consider the broader context in the hybrid welding playbook.

Documentation and validation

Maintain a clear, auditable trail for each weld sequence. Record base material, thickness, weld procedure, filler metal, current, voltage, travel speed, and interpass temperatures. When in doubt, refer to the lab’s accepted PQR templates and ensure your workflow captures both the TIG root and MIG fill passes. The approach here aligns with certification-friendly practices explored in industry-standard playbooks like the process-selection playbook.

Example scenario

A 1.25 in thick carbon steel joint in a fixed-position fixture requires a clean root and moderate fill for a certified test. A TIG root yields a tight, well-fused groove. MIG is used for two passes to build out the contour while carefully controlling interpass temperature to prevent distortion. The plan mirrors guidance from the hybrid playbooks and emphasizes documentation to satisfy lab requirements.

For additional context on hybrid strategies, explore related discussions in the hybrid welding for thick-section joints and the broader hybrid welding playbook.