When to Leverage Dual-Process Joints

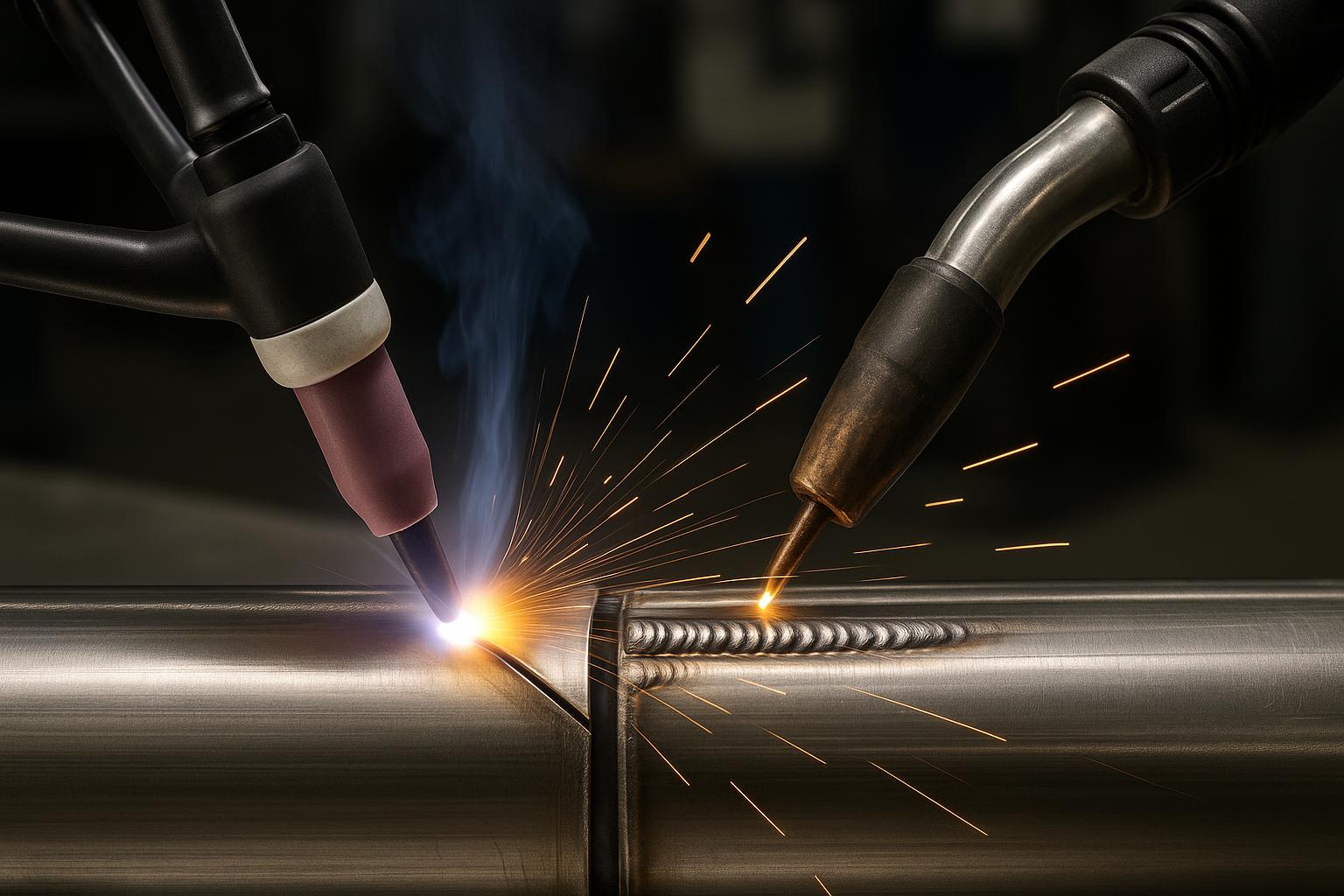

Dual-process TIG-MIG welding combines the precision of TIG with the speed of MIG to optimize heat input and metallurgy in thin-walled structures. It is especially useful when root control and surface quality are critical but full-strength, rapid-fill is still desired.

Key considerations include the metal type, wall thickness, and groove geometry. For example, stainless steel or aluminum thin sections require careful heat management to prevent burn-through or hot cracking. In many cases a TIG root pass provides a clean, deburred root and tight control over penetration, followed by a MIG fill pass to build the joint to specification with consistent bead geometry.

Heat input must be controlled. Use a pulsed TIG root pass to minimize heat in the base metal, then switch to a carefully timed MIG fill pass with lower voltage and faster travel speed to cap the joint without overheating the thin section.

Typical approach by joint type:

- Butt joints on thin-walled sections (0.8–2.0 mm): TIG for root, MIG for fill with short arc length and optimized gas coverage.

- Grooved joints with minimal root gap: TIG root to establish seam, MIG fill with controlled stringer beads.

- Discontinuous geometry or complex contours: pause to inspect root before MIG fill to ensure alignment.

Quality checks and inspection

After welding, conduct a visual inspection, verify bead height and uniformity, and perform dye penetrant testing on the root pass if required by spec. For critical thin sections, consider UT or radiography per project requirements.

For more context on when to blend processes, see our hybrid process strategies and our process playbooks. You can also explore real-world multimode welding approaches in our Real-Time Multimode Welding article.

Key takeaway: TIG root control plus MIG fill can deliver precise, strong joints in thin-wall parts when heat input is carefully managed and verification steps are followed.