WPS and PQR Simplified for New Welders

Starting a welding career or launching a small shop comes with a lot of moving parts. Among them, WPS (Welding Procedure Specification) and PQR (Procedure Qualification Record) can seem mysterious. In practice, they are your roadmap for consistent, code-compliant welds. This post breaks down what inspectors look for, how to prepare WPS/PQR documentation, and practical steps to achieve and maintain code-compliant welds even in a busy shop. You’ll learn how to keep your paperwork in order, what belongs in each document, and how to apply the latest welding technology without getting lost in red tape.

What are WPS and PQR?

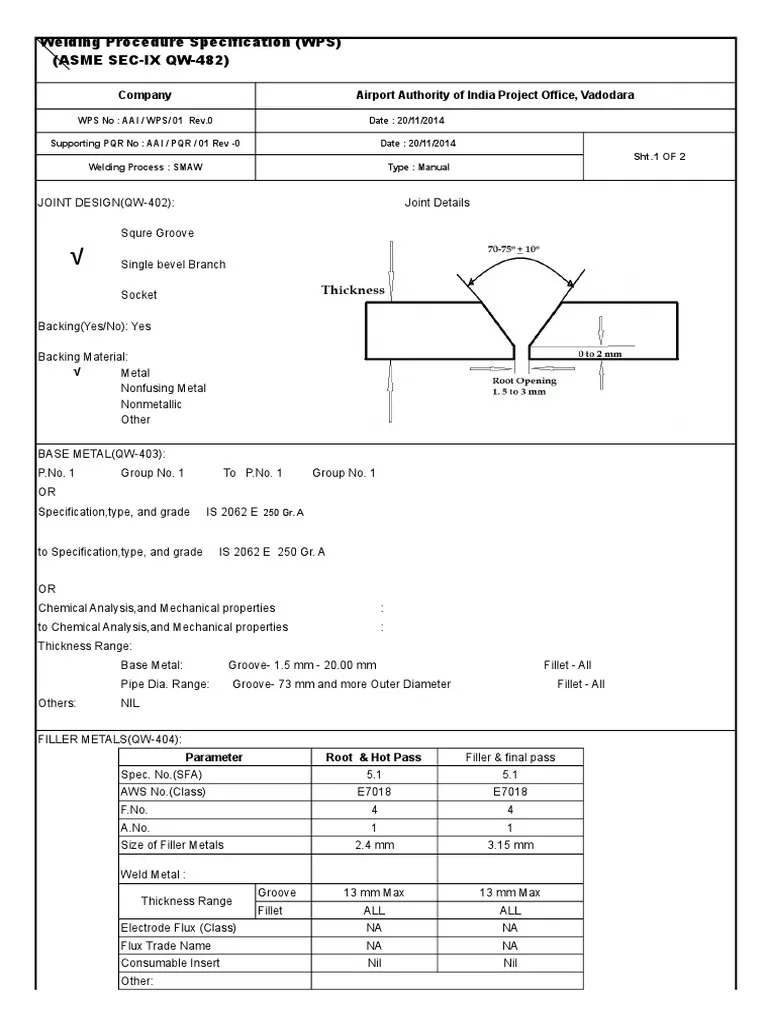

WPS is a written document that provides welding instructions and parameters for a specific process. It tells the welder what process to use, what materials to join, and how to control heat, speed, and procedure so the weld meets code requirements.

PQR is the record of actual tests used to prove that the WPS can produce a weld that meets the stated criteria. It captures the chemistry, mechanical properties, and visual evidence from coupons or test plates, along with the actual parameters used during the test.

Together, WPS and PQR establish a credible chain of custody for weld quality. They define essential variables that affect joint performance and set the baseline for qualification and inspection. Essential variables include the welding process, base metal type and thickness, filler metal, welding position, preheat and interpass temperature, heat input, shielding gas, and any PWHT requirements. Nonessential variables may be documented but do not affect code qualification as long as they stay within reasonable ranges.

There are two practical paths. Prequalified WPS, where the code allows certain combinations of base metal, thickness, process, and joint type to weld without a full PQR. And qualified WPS, where a PQR demonstrates that a specific WPS results in a weld that passes the required tests. In most start up shops, you’ll encounter primarily prequalified routes for simpler welds, and qualified routes for larger or more critical joints.

What inspectors look for in WPS and PQR?

Inspectors use WPS and PQR as the basis for welding quality checks. They look for clear, code-referenced documentation that can be traced to the actual welds in the field or shop. Key items include:

-

- WPS and PQR are present, current, and clearly identified with a code reference and revision level.

-

- All essential variables defined by the code are within the specified ranges.

-

- The WPS specifies the correct process, base metals, filler metals, and thickness ranges for the joint being welded.

-

- The actual welding parameters used on the shop floor or in the test (amperage, voltage, travel speed, wire feed) are consistent with the WPS and within the allowable heat input window.

-

- The PQR documents successful tests, including any nondestructive evaluation results and mechanical test data when required.

-

- Material traceability and heat numbers align between WPS, PQR, and the welded components.

-

- Welder and welding operator qualifications are current and match the processes used on the job.

-

- Any post-weld heat treatment or special procedures are documented and applied as specified.

Finally, inspectors check for proper record retention and accessibility. A well-organized WPS/PQR package should be easy to locate on the job site or in the shop between audits or customer reviews.

How to prepare WPS and PQR documentation?

Preparing WPS and PQR documentation is less about bureaucracy and more about clarity and traceability. A practical workflow looks like this:

-

- Define the code and scope. Decide whether you are working under AWS D1.1, ASME IX, or another standard, and note the specific code references in the WPS.

-

- Collect essential variables. Gather base metal type, thickness, welding process, joint design, position, filler metal, preheat and interpass temperature, and heat input ranges.

-

- Draft the WPS. Include a concise description and a complete list of essential variables. Ensure the WPS is signed off by a qualified person and assigned a unique WPS number.

-

- Plan the PQR test. Identify coupons or plates that will be used, the acceptance criteria, required nondestructive evaluation, and mechanical testing if needed.

-

- Run a procedure qualification. Weld coupons per the WPS under controlled conditions, record all parameters, and document test results, including any nonconformities and corrective actions.

-

- Attach and archive. Link the PQR to the WPS, attach any relevant NDIs or bend test results, and file in a system that supports traceability (digital or paper).

-

- Review and approval. Have the WPS and PQR reviewed by a qualified inspector or supervisor. Update the documentation if the process, materials, or equipment change.

-

- Shop floor deployment. Post or distribute the approved WPS with its number on every relevant welding ticket. Ensure welders know which WPS applies to each joint.

-

- Ongoing maintenance. Periodically re-qualify if there are process changes, material substitutions, or a significant change in welding conditions.

Prequalified vs Qualified: when testing applies

Understanding prequalified versus qualified is a big part of staying code-compliant without overcomplicating your process. A prequalified welding procedure allows certain combinations of base material, thickness, process, welding position, and joint type to be welded without a separate PQR for every project. The code defines bounds within which a WPS is considered prequalified. If your joint falls outside those bounds or you need a different combination of variables, you must qualify the procedure with a PQR and establish a fully qualified WPS.

In practice, this means that many routine shop welds can rely on prequalified WPS to speed up production. But when you weld unusual materials, thick sections, limited access positions, or specialized joints, you will likely need a procedure qualification record that demonstrates the WPS can produce a weld that meets the code’s acceptance criteria. In turn, your WPS becomes the qualifying document for those materials and configurations.

Practical steps for startup shops to stay compliant

Startups benefit from a simple, scalable approach to WPS and PQR management. Here are practical steps that keep you competitive while meeting code requirements:

-

- Build a starter library of WPS templates for common processes and base metals. Include essential variables and code references in a consistent format.

-

- Use templates for PQR data sheets that capture the test setup, specimen details, and acceptance criteria. This reduces repetitive work and minimizes omissions.

-

- Invest in a lightweight record-keeping system. A digital folder structure with version control makes it easy to retrieve the latest WPS and PQR for audits or customer reviews.

-

- Label every weld ticket with the exact WPS number and the welder or welding operator’s qualification details. Traceability reduces questions during inspections.

-

- Involve a competent person for approvals. A certified welding supervisor or CWI can review WPS content and PQR test results, preventing nonconforming documentation from slipping through.

-

- Plan for revisions. If you change the welding equipment, filler metal, or base metal, you may need to update the WPS and possibly re-qualify with a PQR.

-

- Train welders on the meaning of essential variables and why each item matters. Strong front-end training reduces misapplication on the shop floor.

-

- Leverage automation and measurement. Modern practice can help you monitor interpass temperatures and heat input, ensuring consistent results across shifts.

Key Takeaways

-

- WPS and PQR provide a documented path to code-compliant welding with traceability from materials to welds.

-

- Essential variables define the controllable aspects of a weld; staying within their limits is critical for qualification and inspection success.

-

- Prequalified WPS simplify routine work; PQR-based qualification is required for non-prequalified cases or complex configurations.

-

- Keep WPS and PQR up to date, well organized, and easily accessible for auditors and customers.

Conclusion

WPS and PQR are not red tape, they are the backbone of repeatable, quality welding. With a practical approach to documentation, you can streamline qualification, improve job-site confidence, and build a foundation for scalable welding operations.