Using Real-Time Data to Stabilize Consistent Weld Quality

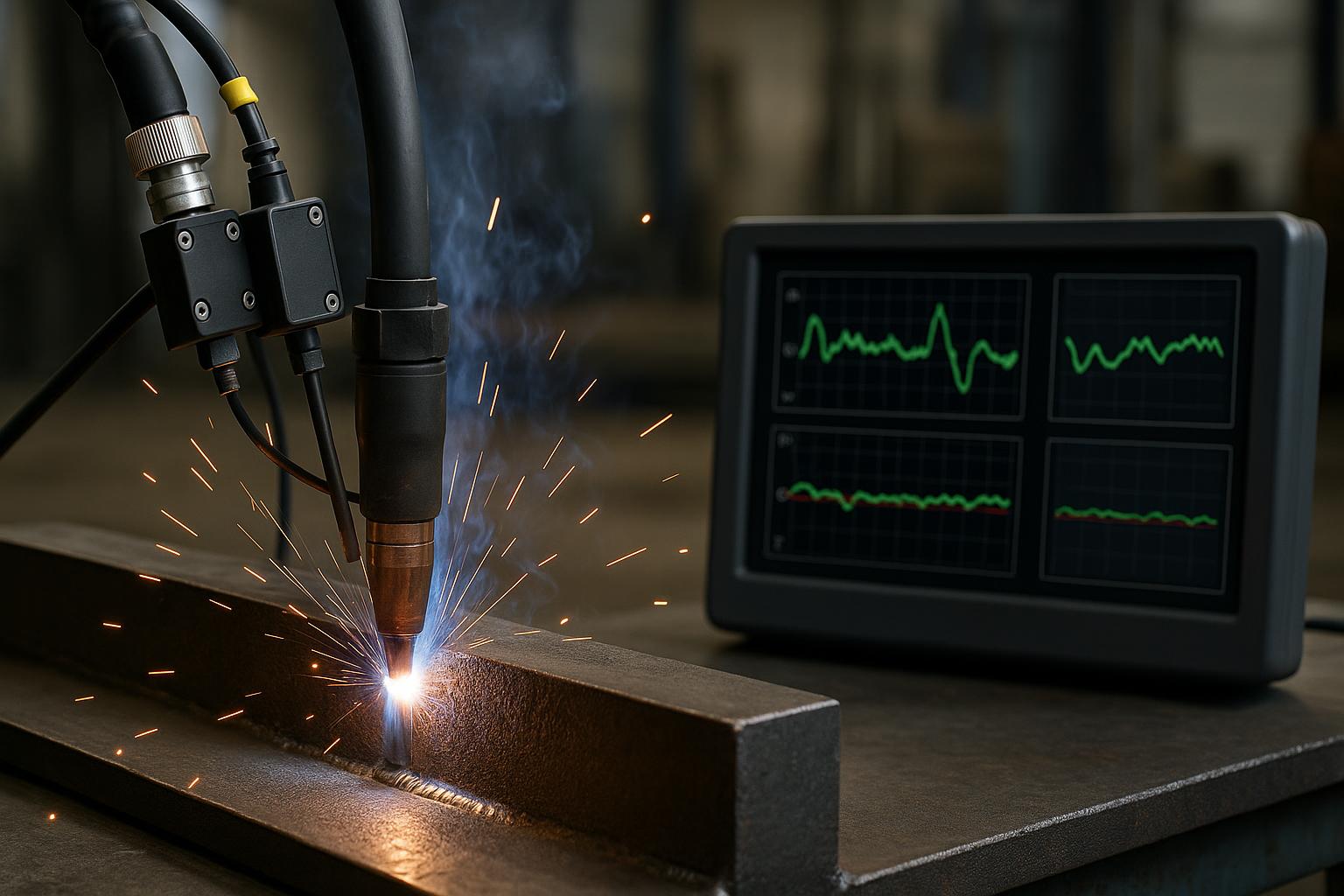

Real-time process monitoring relies on sensor data from arc voltage, current, wire feed, and bead geometry to capture every weld pass. This data supports immediate adjustments and long-term trend analysis, helping teams minimize rework. This aligns with the process selection playbook for setting up monitoring plans.

Waveform analysis and SPC drive better decisions

To translate raw signals into actionable insight, practitioners perform waveform analysis to extract features such as arc stability and melt pool behavior. This insight informs immediate control decisions and ongoing process improvements. In many shops, waveform features feed AI-driven quality checks to catch anomalies before they trigger rework.

Linking data to standards and code

Statistical process control (SPC) helps distinguish common variation from drift, enabling a shop to set realistic control limits and reduce rework. Regular SPC reviews create a feedback loop between operators and engineers. This approach pairs well with welding code updates to stay compliant while optimizing quality.

Practical steps for daily production

- Instrument your torch with durable sensors and verify data integrity before each shift.

- Set baseline SPC limits using recent production data.

- Review waveform features weekly and act on drift promptly.

- Incorporate lean automation ideas to streamline data collection, see lean automation upgrades.