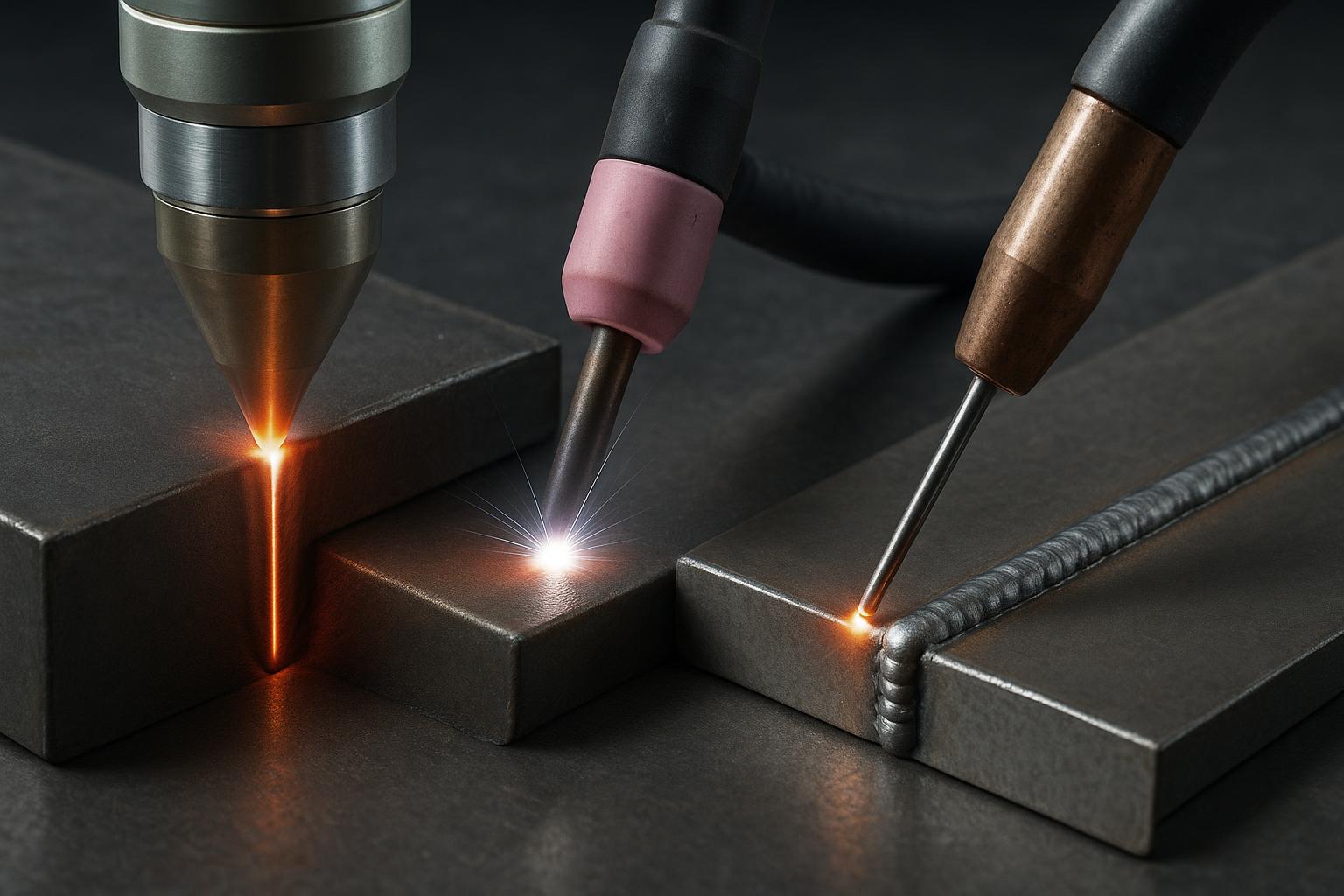

When to Combine Laser, TIG, and MIG for Thick vs. Thin Joints

Hybrid welding that blends laser, TIG, and MIG can unlock faster production, lower cost per joint, and superior quality when used at the right times. The core decision is guided by joint thickness, material behavior, and the acceptable level of heat input.

For thick joints (3 mm and up, or substantial gaps), a high-energy laser pre-weld or root pass can dramatically reduce weld time. A filler wire from MIG can fill gaps quickly, while TIG finishing can control heat input and provide precise bead shaping. See how this approach aligns with the realities of thick-section joints in related guides like hybrid welding and process-selection thinking in process selection.

For thin joints, the risk is overheating and distortion. In these cases, a laser-TIG-MIG hybrid can still help by delivering a small laser penetration followed by TIG for precision and MIG for a clean bead, but adjustments are tighter and expected outcomes are tighter tolerance. Real-world examples from shop floors show why controlled heat input and synchronized travel speed matter, as discussed in case studies.

Decision framework for thickness and joint type

- Thick joints: use laser to deposit deep, narrow penetration, MIG to bridge gaps and deposit filler efficiently, then TIG to finish with low heat and precise contour control.

- Thin joints: prefer minimal heat input; keep laser power low, MIG for bridging only, TIG for finish and polish where tight tolerances matter.

- Critical geometry: when bead profile or distortion tolerance is demanding, sequence the passes to control heat flow and use TIG for post-weld shaping.

- Cost vs. quality: weigh per-joint cost against defect risk; hybrids often save money where traditional single-process welding would require multiple passes or rework.

Setup tips for successful hybrids

Coordinate laser, TIG, and MIG power sources with a common travel plan. Start with a clean, square joint prep, then validate fit-up with a light tack. Choose a shielding gas strategy that protects both laser-assisted welds and arc welding zones—often mixed gas for TIG and MIG helps maintain stability near the laser zone.

Filler metal selection matters: use a TIG-compatible alloy for finishing passes and a MIG wire suited to the base metal. Align torches carefully to minimize misalignment and ensure consistent heat distribution across the joint. For beginners, practice on coupon plates that simulate both thick and thin sections before proving out a production run.

Real-world case studies

In a recent mid-volume fabrication job, a laser pre-weld reduced root defect rates while MIG filled gaps on thick joints. The subsequent TIG finishing produced tight bead profiles with limited distortion, delivering a lower overall cost per joint. See how similar decisions are applied in more detail in hybrid welding for thick-section joints.

A separate shop compared pure MIG welding of a thick flange to a laser-MIG-TIG hybrid approach. Although the upfront equipment cost was higher, the hybrid method cut total cycle time by nearly 40% and improved bead consistency. For a broader process framework, review the process selection playbook.

For ongoing education, the multimode welding angle offers a staged approach to integrating laser and arc processes; this is discussed in broader terms in real-time multimode welding.