Real-Time Feedback That Improves Certification Pass Rates

Arc-length sensing and closed-loop control give real-time feedback to the welder, allowing bead profiles to stay within spec during AWS/ASME tests. This approach helps reduce test failures caused by small arc-length variations and inconsistent weld geometry.

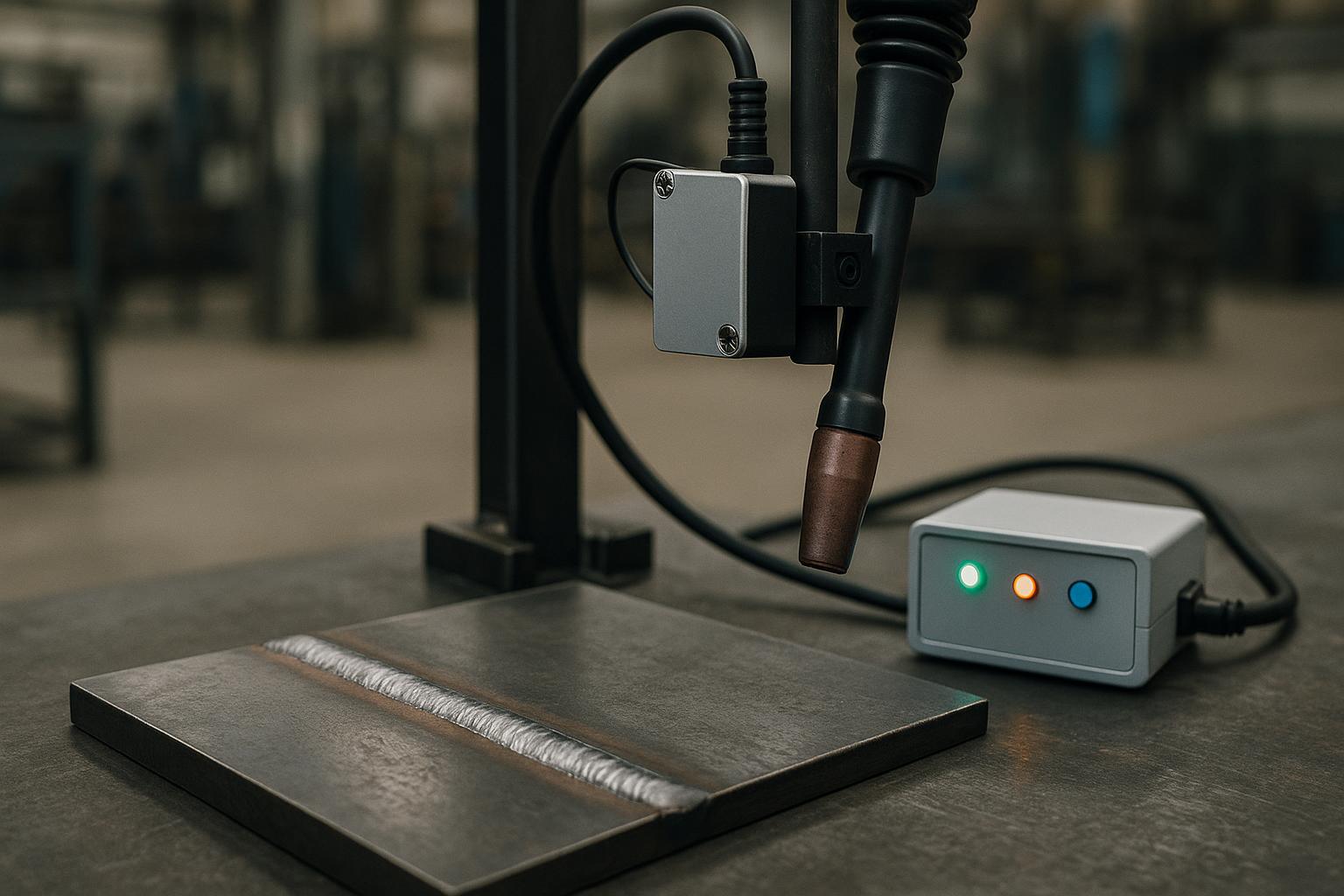

Overview: The system uses a sensor near the arc to measure the distance to the workpiece, feeds data to a controller, and adjusts process parameters to hold a target arc length. This is particularly useful on training rigs where repeated test joints are used to build muscle memory and procedural discipline. This concept aligns with our disciplined practice routines in the certification test day prep guidelines.

Key components for arc-length monitoring

- Arc-length sensor: a compact device that measures the distance from the arc to the workpiece in real time.

- Controller: a processor that runs a closed-loop algorithm to keep arc length at target.

- Training jig: a repeatable test rig that simulates AWS/ASME butt joints.

- Actuators or process controls: ability to adjust current, wire feed, or travel speed to maintain the arc length.

Setting up on a training rig

Calibrate your baseline arc length on a series of test beads. Use a standard test plate and a butt-joint jig designed for AWS/ASME mock exams. Connect the sensor to the controller and set a target arc length based on your common welds — for example, a 2–3 mm gap in short-arc positions for a 1/8 in plate. The system will nudge process variables to bring deviations back toward the target length.

For practical reference, review our certification test day guidance to structure practice sessions around typical pass/fail criteria.

How to measure improvement

Use consistent bead profiles to measure success. Track bead width, height, and penetration across multiple passes, and compare mock-cert runs before and after enabling arc-length monitoring. You should see reduced bead-to-bead variation and a more predictable heat input, which translates to higher pass rates on AWS/ASME tests.

In addition to technical setup, solid practice scheduling helps. See the certification timeline toolkit to plan progressive goals and practice blocks that target common failure modes.

Practical steps to get started

- Define target arc length for your most common joint and material combo.

- Choose a compact, shop-friendly arc-length sensor and a controller with a simple tuning interface.

- Wire the sensor data to a control loop that can adjust current or wire feed in real time.

- Run short, focused practice blocks, recording bead profiles and pass outcomes to refine the target and control gains.

Early experiments with arc-length monitoring often benefit from insights in our certification hacks for efficient prep and troubleshooting.

With this approach, you’ll stabilize bead profiles during AWS/ASME tests, improving consistency and boosting overall pass rates.