How to Design Realistic Certification Fixtures to Harden Test Outcomes

Creating field-accurate certification fixtures is about more than making a joint fit and a weld; it’s about shaping the conditions welders will face on AWS and ASME tests. Realistic fixtures expose workmanship gaps and process variability early, allowing teams to train under controlled but representative stress. This article outlines practical steps to design fixtures that replicate vibration, lighting, and fit-up challenges while remaining repeatable and measurable.

First, define the target test scenario. Review the AWS and ASME qualification standards and pick a representative joint type, material, and thickness. Document the required clamp forces, gap tolerances, and angular alignment. This baseline becomes the benchmark for every fixture you design. For guidance on how fixture choices map to certification outcomes, see how others structure their smart fixtures and portable test stations.

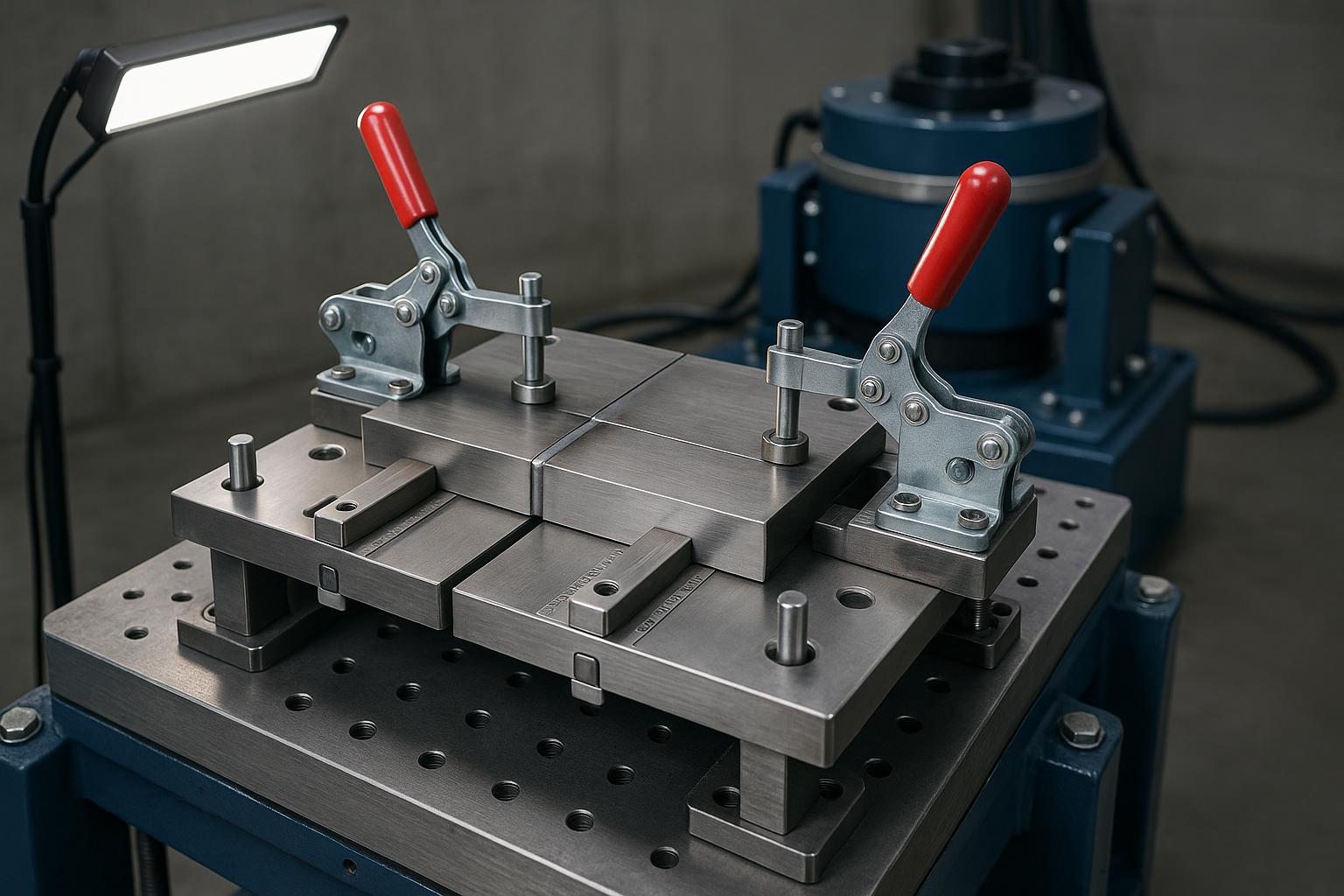

Next, design fixtures to enforce consistent joint fit-up. Use alignment pins, fiducials, and calibrated clamps to ensure every weld starts from a known position. Document the fixture geometry and record the actual joint gaps per test to build a data set you can review before and after each run. A practical approach is to pair a fixed base with removable inserts so you can simulate different fit-up scenarios without rebuilding the fixture each time.

Incorporating vibration and lighting

To mimic field conditions, add a shake table or vibration mechanism tied to a defined spectrum that aligns with typical shop floor dynamics during pass-fail criteria. Add lighting that reproduces the AWS/ASME test environment: consistent, shadow-minimizing illumination at the weld joint with glare-free angles. These factors influence operator performance and defect detection during practice runs.

Validation and iteration

Run a small batch of mock tests, log weld quality, and compare with the baseline acceptance criteria. Use repeatable fixtures to measure defect rates and time-to-weld. Track improvements as you adjust fixture features.

For broader context, explore how others approach certification readiness in related posts such as certification test day and certification testing under pressure.