Optimizing GTAW and FCAW Sequences for Certification-Friendly Joints

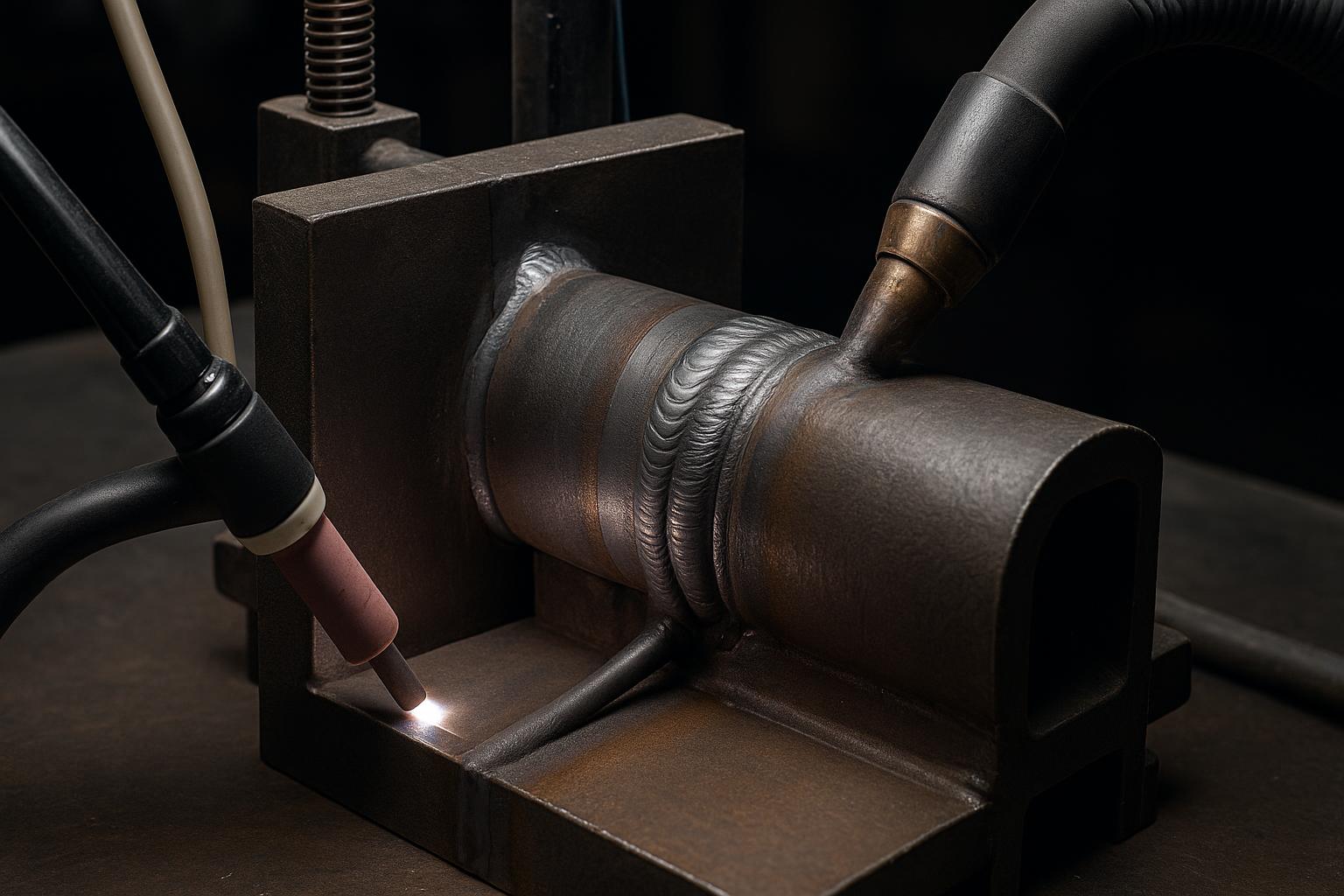

Thick-walled joints challenge even experienced welders because heat input, penetration, and joint fit must be tightly controlled. The goal in a single certification trial is to produce a defect-free weld across the full thickness while satisfying exam criteria for both TIG (GTAW) and MIG (FCAW) processes. The approach below uses a coordinated sequence: GTAW root, FCAW fill, and GTAW cap, ensuring proper penetration, bead geometry, and heat balance.

For deeper guidance on sequencing decisions within a real exam timeline, see the process-selection playbook.

Recommended three-pass sequence

- GTAW root pass: establish a clean trench with tight root penetration, minimal weaving, and a controlled heat input. This pass helps prevent lack of fusion at the root and reduces the risk of burn-through on thick sections. Use a small-diameter tungsten and argon purge as needed.

- FCAW fill passes: apply the bulk metal with controlled, even deposition. Maintain a steady travel speed and a consistent arc length to avoid slag inclusions and porosity. Clean between passes as needed to ensure good fusion.

- GTAW cap pass: finish with a TIG-cap bead that blends with the fill metal, provides a smooth contour, and seals the joint. Keep heat input moderate to prevent distortion and ensure surface finish meets exam standards.

For a broader look at certification prep and how it maps to exam standards, consider the certification-day guidance in certification test day.

Parameter guidelines (high-level)

- GTAW root: low-to-moderate heat input, short arc, minimal dilution, and proper purge.

- FCAW fill: higher deposition rate with stable arc, adequate cooling between passes to avoid heat buildup.

- GTAW cap: low heat input to shape the bead and minimize distortion, with careful contour control.

Defect-prevention strategies

- Ensure tight fit-up and clean joint surfaces before welding.

- Back purge for closed roots and ensure proper shielding gas coverage to prevent porosity.

- Control heat balance across passes to avoid cracks, warpage, and lack of fusion.

- Inspect weld beads between passes and verify alignment with the joint geometry.

Using purpose-built fixtures and alignment aids can greatly improve consistency in thick-section welds. See how fixtures support certification-ready work in Smart Test Fixtures.

Documentation matters. Gather a clear WPS, PQR, and welder notes that reflect the actual trial parameters. This aligns with the framework outlined in the certification test day and helps ensure the examiner can validate the procedure and results.