Turning Sensor Data into Weld Quality Confidence

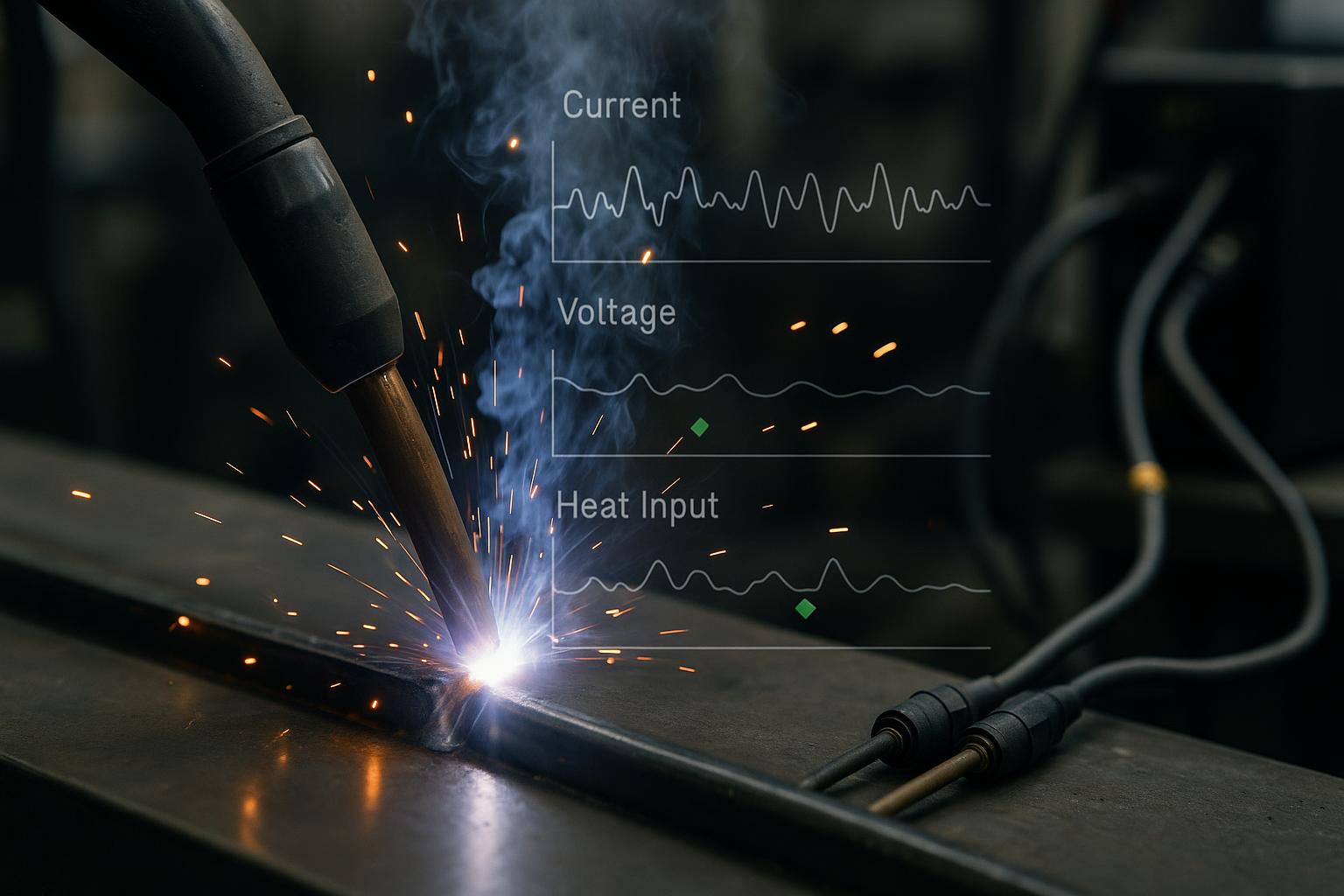

Real-time arc analytics combines sensor data from the welding arc—current, voltage, and arc length—with waveform analysis to reveal how the arc behaves under load. By interpreting these signals in real time, shops can implement in-process controls that improve consistency and repeatability across welds.

Getting practical requires a straightforward setup and a clear interpretation framework. Start with baseline sampling, establish acceptable waveform shapes, and define defect markers you can act on immediately.

In-Process Setup Tips

- Enable high-sample-rate data capture for current and voltage (e.g., 1–10 kHz) to resolve arc transients.

- Set threshold bands for stable voltage and current; flag deviations for near real-time adjustment.

- Document baseline waveform profiles for typical joint types you weld (fillet, butt, etc.).

For a deeper look into monitoring strategies, see smart process monitoring.

Reading Waveforms and Defect Markers

- Waveform irregularities can indicate arc wander, inconsistent heat input, or improper gas shielding.

- Defect markers may appear as trend shifts, spikes, or damped oscillations; interpret these in context with process parameters.

- Learning to correlate specific waveform features with defects lets you adjust travel speed and amperage on the fly.

Learn more about how AI can flag defects with AI-driven quality checks.

Linking Metrics to Quality Outcomes

Turn measured metrics into repeatable control settings. Example: keep arc current within ±5 A and maintain a stable impulse profile; capture a quick before/after snapshot to verify improvements against your quality goals.

In practice, teams combine arc analytics with structured documentation to drive continuous improvement. For an approach that ties analytics to certification readiness, see data-driven certification prep.