Real-Time Arc Monitoring for Certification-Ready Welds

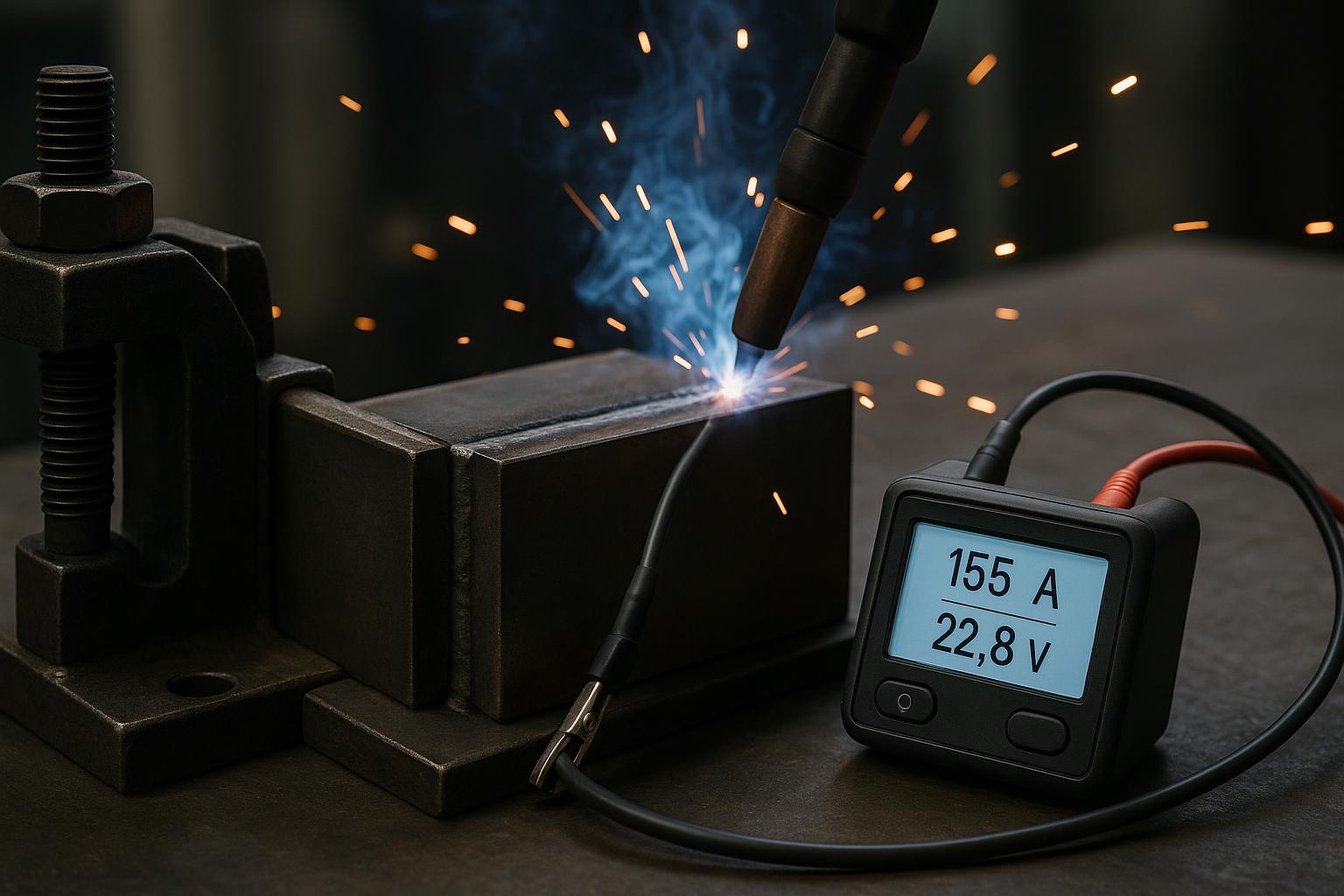

Real-time arc monitoring uses affordable sensors and data logging to improve consistency in welds used for both certification tests and production joints. By recording current, voltage, and arc length during a run, you can identify drift and adjust technique before it costs a pass or fail.

Low-cost sensor options

For an affordable setup, you can combine a compact current sensor and a voltage probe with a basic data logger or microcontroller. A typical configuration includes a Hall-effect or shunt-based current sensor, a simple voltage sensing circuit, and a small data-logging module that stores CSV data for later review. This keeps the cost down while giving you repeatable measurements on test coupons and production joints.

- Current sensing with a small shunt or Hall-effect sensor to monitor arc stability

- Voltage sensing across the arc to detect fluctuations in arc voltage

- Loggable sampling around 50–200 Hz to capture key transients without overflowing memory

Data logging and interpretation

Export the data to CSV and plot the arc current and voltage over time. Look for smooth curves and minimal fluctuations; spikes often indicate contact instability or inconsistent filler metal transfer. Compare data across passes to drive consistent heat input and penetration. For practical certification steps, you can study how to prepare for the exam by reading certification test day.

Putting it into shop practice

To implement in your shop, follow a simple 4-step plan: define target stability metrics, assemble the sensor kit, run test coupons with logged data, and review results to adjust technique. Using fixtures that hold sensor probes and the workpiece steady helps reduce setup variability; see smart test fixtures for ideas on rigid, repeatable test setups.

For scheduling and tracking progress toward certification deadlines, refer to the certification timeline toolkit.