Matching Weld Methods to Joints, Metals, and Deadlines

Choosing the right welding process starts with the job constraints: joint geometry, base metal, thickness, and the production schedule. A disciplined framework helps shop teams pick MIG, TIG, FCAW, or SAW efficiently while controlling cost and quality.

Key factors to evaluate

- Joint design: butt, lap, corner, or fillet joints determine heat input and technique advantages.

- Base material and thickness: steel, aluminum, stainless, and gauge affect selection, filler metal, and travel speed.

- Required quality and codes: critical-pass joint specs may push you toward TIG or SAW over FCAW.

- Production rate and deadlines: high-volume production often favors processes with higher deposition rates.

- Accessibility and fit-up: tight tolerances or difficult access may limit options.

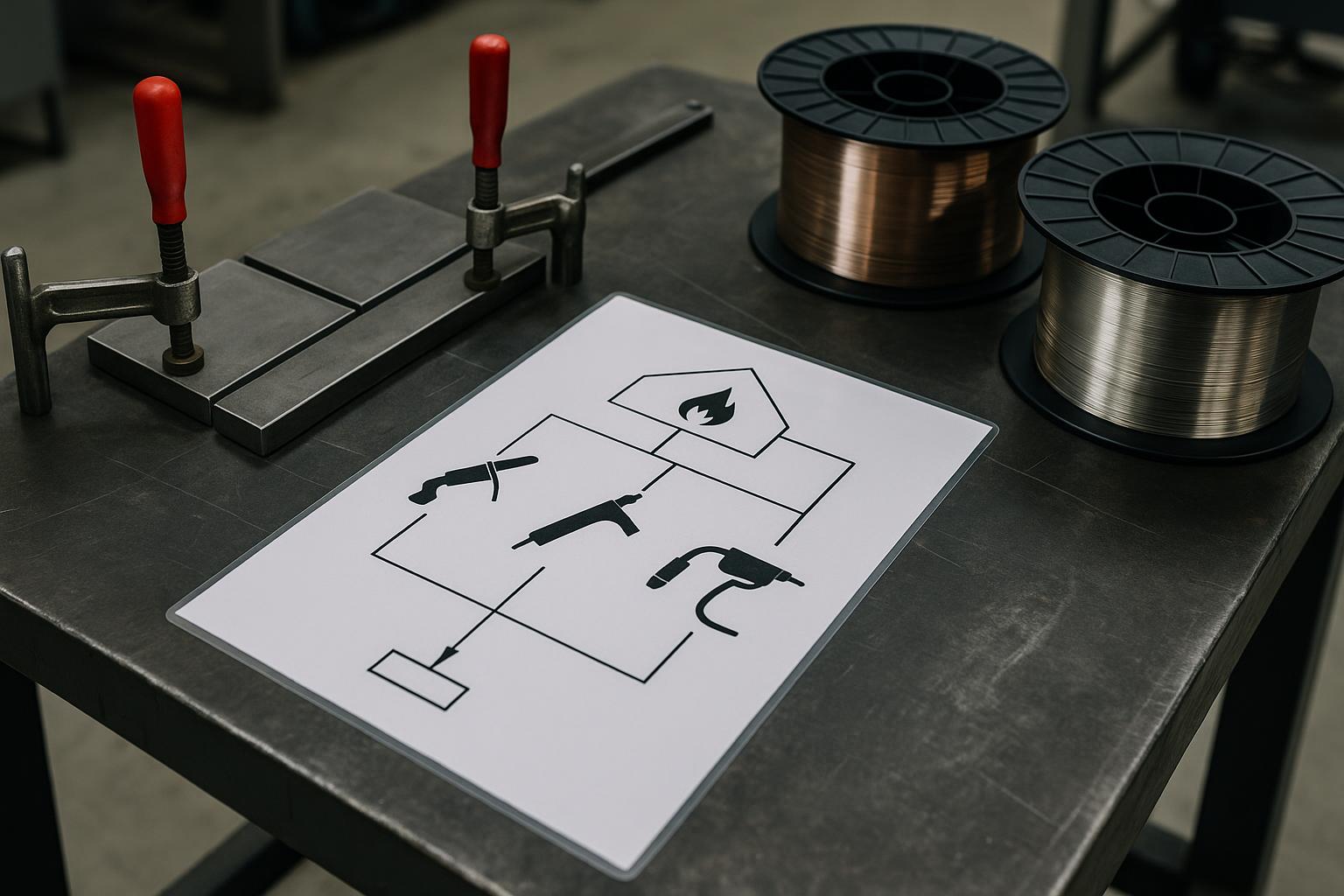

How a decision tree helps

Start with a simple decision tree: Is the joint critical for load? If yes, choose TIG or SAW for precision; if not, FCAW or MIG may suffice. Factor material type and thickness, then confirm with lead-time and cost targets. A written framework reduces guesswork on the shop floor.

For a practical reference, see our related posts on shop automation and process capability. lean automation upgrades and WPS and PQR basics.

Real-world scenarios

- Light-frame fabrication for an EV sub-assembly: Use MIG for speed, with FCAW as a backup for thicker sections. Consider stand-off fixtures to keep travel times predictable.

- Aluminum bicycle rack with corrosion control: TIG offers clean welds, but a carefully tuned TIG process or TIG with a backing gas shield may be required for aesthetics and corrosion resistance.

- Structural steel prismatic brackets with tight tolerances: SAW or TIG when precision matters; MIG/FCAW for non-critical joints to meet deadlines.

Expand your capabilities

To broaden your shop’s high-value work, map your process-selection framework to potential services and pricing. For guidance on business growth and pricing strategy, see Starting a Welding Business: Niche, Pricing, and Demand and Pricing Your Welding Services for Startup Profit.

By documenting the decision criteria and aligning them with your current equipment, you can win more high-margin jobs without sacrificing quality.